Best of Both Worlds (Part 1): Hybrid Wall Assemblies

For hybrid wall assemblies in 2” x 6” wood framing in climate zones 5 through 7, CSFI recommends a minimum of 2” of ccSPF.

Homeowners and builders often ask us what type of spray foam insulation (open-cell or closed-cell) they should use. The prescriptive code-compliant answer says ocSPF for climate zones 1 – 4 and ccSPF for zones 5 – 8. Other potential customer requirements such as increased racking strength enabled by ccSPF, the reduction in sound transfer attributed to ocSPF, or budget constraints can complicate things. In these situations, a hybrid assembly becomes an attractive option.

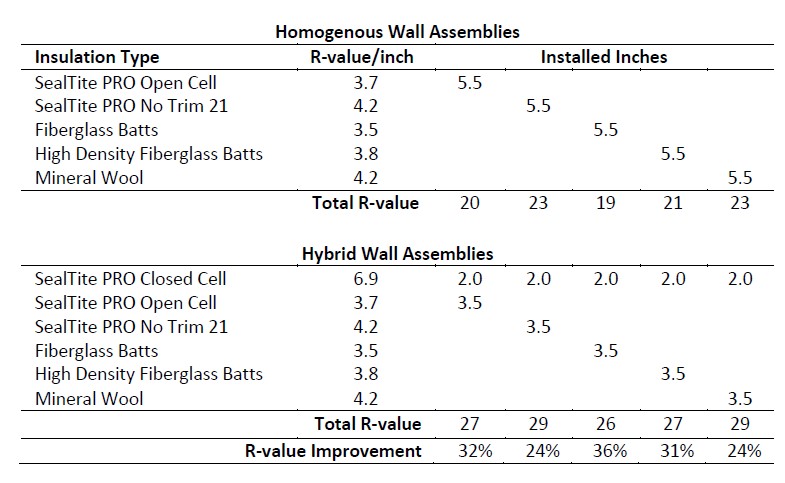

We define a hybrid assembly as a system that combines two dissimilar insulation product types to achieve total assembly performance and cost targets that cannot be attained from a single product type. The following table summarizes how hybrid systems reach high R-values without having to use four or more inches of ccSPF.

This article examines the proper installation of spray foam in hybrid wall assemblies, and the building science principles behind these recommendations.

Recommendation 1: Always install ccSPF first

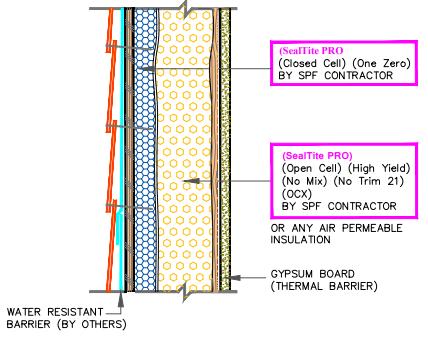

We recommend applicators install ccSPF directly to the wood substrate in hybrid assemblies to improve structural strength and eliminate vapor retarders.

We recommend applicators install ccSPF directly to the wood substrate in hybrid assemblies to improve structural strength and eliminate vapor retarders.

Closed-cell SPF improves the racking strength of wood-framed walls by as much as 300%. Not installing ccSPF directly to the wood sheathing unnecessarily sacrifices this feature.

In colder climate zones, building code requires the use of a class 2 vapor retarder (< 1 perm per ASTM E96) installed on the interior side of the building. The vapor retarder prevents warm moist interior air from migrating through the wall and condensing on the cold wood substrate. We eliminate this requirement by maintaining a warm enough temperature inside the wall assembly, preventing condensation from occurring. To accomplish this, code allows the use of plastic insulating sheathing as continuous insulation on the exterior side of framed walls or SPF with a maximum permeance of 1.5 perms at the installed thickness applied to the interior side (2021 IRC R702.7.1). These wall designs keep the vapor-permeable insulation warm enough to eliminate condensation risk and allow for interior drying.

Recommendation 2: Minimum of 2” of ccSPF

An effective hybrid wall assembly prevents water vapor from condensing by maintaining a temperature above the dew point. How much ccSPF is needed to accomplish this? Condensation potential can be modeled using software tools, but the code simplifies this by telling us exactly how much R-value is needed. This table indicates the minimum R-value required for condensation control purposes in 2” x 6” framing. Most ccSPF products satisfy the R-value requirement for climate zones 5 and 6 at 2”.

| Climate Zone | Minimum R-Value |

| 5 | 7.5 |

| 6 | 11.25 |

| 7 | 15 |

Some high R-value ccSPF products may meet climate zone 5 and 7 requirements at 1” and 2” respectively. However, meeting the <1.5 perm vapor permeance performance of that SPF product may require greater thicknesses than what R-value recommends.

Consider a ccSPF product with an R-value of 7.5/inch and a vapor permeance of 1.7 perms/inch in climate zone 5. This product needs to be installed at a thickness greater than 1” to satisfy both requirements. SealTite™ PRO Closed Cell has an R-value of 6.9 at 1” and a vapor permeance of 0.8 at 1”. Both products meet one criterion at 1” but not both. Specific ccSPF product permeance rating becomes especially important in hybrid assemblies if you assume some cavity spots may be thinner than needed. A slightly underfilled location creates a potential pathway for water vapor to travel and potentially condense. SealTite PRO Closed Cell or One Zero, with their really low perm ratings, provide a high safety factor at 2” applications.

Installing ccSPF that fails to meet the 1.5 perm requirement is permissible, but you would have to install a class 2 vapor retarder on the interior, which is the one step we are trying to avoid in the first place. While we are on this subject let’s briefly talk about flash and batt.

We don’t consider a flash and batt installation technique a hybrid assembly. A flash pass (<1”) of ccSPF followed by installation of a fiberglass or mineral wool batt insulation is an air-sealing strategy. Flash and batt assemblies don’t fully leverage the properties of ccSPF because the structural strength and water vapor permeance features aren’t realized with thin applications of ccSPF. Effective flash and batt systems in climate zones 5-8 require a class 2 vapor retarder.

Finally, 2” of ccSPF leaves 3.5” of usable space, which easily accommodates many commercially available insulation product options to completely fill the remainder of the cavity and attain desired R-value.

A properly installed hybrid wall assembly makes a tighter, stronger, and quieter wall system than would otherwise be possible using a single product type. Using just enough ccSPF to realize its full benefits and filling the remainder of the cavity with a different insulation product type reduces the per square foot installation costs, giving builders and homeowners a potentially more cost-effective option for achieving their energy efficiency goals in cold climate zones.

We will examine hybrid attic and ceiling assemblies in a future article, so stay tuned!