Best of Both Worlds (Part 2): Hybrid Attic and Ceiling Assemblies

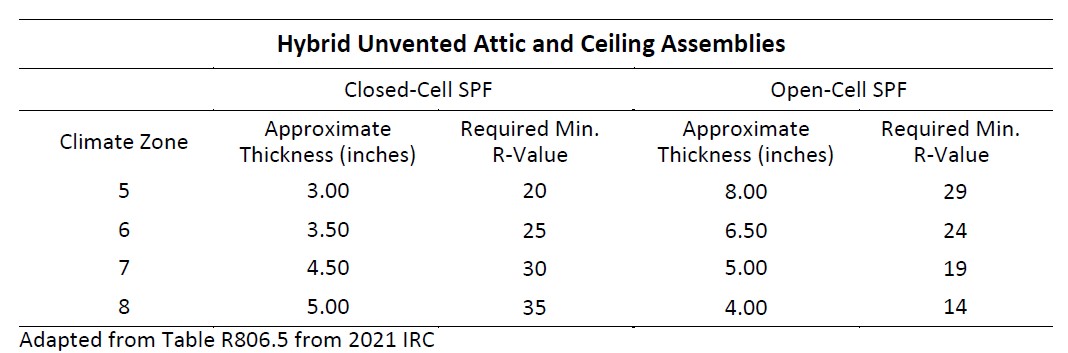

For hybrid attic and ceiling assemblies, the recommended amount of closed-cell SPF depends on the climate zone.

The previous PRO Tip discussed how to create hybrid wall assemblies with closed-cell SPF and either open-cell SPF or traditional fibrous insulation types. This article extends the conversation to attic and ceiling assemblies in climate zones 5 – 8.

The previous PRO Tip discussed how to create hybrid wall assemblies with closed-cell SPF and either open-cell SPF or traditional fibrous insulation types. This article extends the conversation to attic and ceiling assemblies in climate zones 5 – 8.

As a reminder, we defined a hybrid assembly as a system that combines two dissimilar insulation product types to achieve total assembly performance and cost targets that cannot be attained from a single product type. Closed-cell SPF provides improved structural strength, high R-Value, a class II vapor retarder, and air sealing, whereas open-cell SPF (also air-sealing) and fibrous insulation deliver improved sound attenuation and cost effectiveness. This article focuses on unvented attics and cathedral ceilings.

The same recommendations and principles introduced in the previous PRO Tip for hybrid walls apply to hybrid unvented attics and cathedral ceilings – (1) Always install closed-cell SPF first, and (2) there must be a minimum amount of closed-cell SPF. In this article, we provide an additional recommendation unique to unvented attics specifically for insulation contractors who consider a hybrid approach.

Recommendation 1: Always install closed-cell SPF first

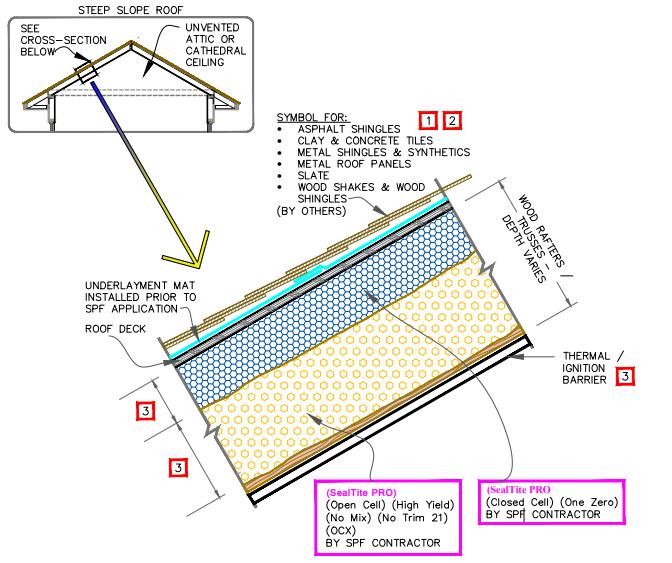

Installing closed-cell SPF directly under the roof deck improves the wind uplift resistance of the entire roof. A 3” filet of SealTite™ PRO Closed-Cell under the roof deck achieves an uplift resistance of 190 lbs per square foot. Closed-cell SPF acts as an incredibly strong adhesive, securing the roof to the joists or rafters. Homeowners and builders typically value this feature more in regions prone to hurricane-strength winds, but if already installing closed-cell SPF, installing the foam directly to the roof sheathing takes full advantage of what the foam offers.

The second reason to install closed-cell SPF seeks to eliminate the need for class II vapor retarders. If these reasons sound familiar to you, it is because they replicate what we introduced for walls in the previous PRO Tip. However, there is a significant practical difference. Eliminating the class II vapor retarder has exponentially more importance in attics because attics pose incredible installation challenges for typical class II vapor retarders. What amounted to an inconvenient additional step for framed walls becomes exponentially more difficult in an unvented attic. When using spray foam, building code essentially limits the class II vapor retarder options to liquid-applied products. Imagine installing any plastic sheeting in an attic that meets the requirement set in section R806.5 of the IRC:

“In Climate Zones 5, 6, 7, and 8, any air-impermeable insulation shall be a class II vapor retarder or shall have a class II vapor retarder coating or covering in direct contact with the underside of the insulation.”

The variations in the spray foam surface (open-cell or closed-cell) make direct contact an almost impossible task without a liquid-applied product. Eliminating the need for this step becomes desirable and worthwhile. Installing closed-cell SPF first and at the right amount eliminates this requirement.

But wait…wouldn’t it make more sense to install open-cell SPF first and then use closed-cell SPF as the class II vapor retarder? This is a viable option consistent with building code requirements, but we don’t typically recommend this assembly for two reasons. First, closed-cell SPF under open-cell SPF is not an efficient use of closed-cell SPF. More cost-effective class II vapor retarder options exist since you will probably need to install enough closed-cell SPF to reach class II vapor retarder properties, (between 1 – 2 inches for most closed-cell SPF products). This approach also eliminates the wind uplift resistance performance. Secondly, though compatible, open-cell SPF is not a preferred substrate for closed-cell SPF. We advise that the lighter, less dense foam be installed to the heavier, denser foam.

Recommendation 2: The amount of closed-cell SPF depends on the climate zone

We eliminate the class II vapor retarder requirement by providing enough air-impermeable insulation directly under the roof sheathing to control condensation. Remember though that in climate zones 5 – 8, the air-impermeable insulation must be closed-cell SPF.

The “correct” amount of closed-cell SPF directly under the roof deck permits the use of open-cell SPF without a vapor retarder. The same reasoning from the previous article applies here as well. Like an effective hybrid wall assembly, an effective attic and cathedral ceiling assembly prevents water vapor from condensing by maintaining a temperature above the dew point. The IRC again outlines what the “correct” amount of closed-cell SPF means. But unlike in walls, where 2 inches of closed-cell SPF satisfied this requirement in climate zones 5 – 7, the amount of closed-cell SPF in attics and ceilings varies depending on the severity of the climate zone. Higher climate zones require a greater proportion of closed-cell SPF relative to the total R-value of the system. The table below summarizes the code-compliant amounts of closed-cell SPF and open-cell SPF to control condensation without additional interior class II vapor retarders.

Recommendation 3: Consider other potential costs

Hybrid attics and cathedral ceilings reduce the total material cost of the system by replacing some closed-cell SPF with a more cost-effective insulation type. Limiting the use of closed-cell SPF to an amount that provides the most benefit with the least amount of material potentially makes each set of your closed-cell SPF go further. Hybrid attics offer an even more impressive potential cost savings than walls due to the higher R-values needed. Reducing the use of closed-cell SPF in a wall from 3” to 2” shows much less cost savings than an attic in zone 5 that reduces the required closed-cell SPF use from 7” to 3”.

Despite the total material cost savings, insulation contractors should consider two potential expenses that could alter the economic benefits.

Most closed-cell SPF products pass the NFPA 286 Appendix X test, which eliminates ignition barrier requirements. In a hybrid assembly with open-cell SPF facing the interior, an ignition barrier will likely now be required unless the open-cell SPF has approval from an alternate test method, or an OCX type foam is used. The cost of intumescent coatings at ignition barrier thicknesses slightly reduces the total cost savings. If the SPF requires a thermal barrier, we suggest accounting for possible increased use of intumescent coating due to the more uneven surface of the open-cell compared to closed-cell.

Single spray foam installer rigs will also need to carry two types of products to the jobsite and require a changeover to switch from the closed-cell to the open-cell product. In this situation, make sure any lost material and unproductive downtime costs are calculated into your own analysis. Contractors running multiple rigs with dedicated product types eliminates these costs and helps you fully realize the economic benefits.