Regular to Winter Closed Cell Transition

Winter is coming, and that means that it may be time to transition to winter-speed closed-cell spray foam insulation products. Before addressing some of the things to consider when converting from regular speed to winter speed products, let’s begin with a quick explanation of why some SPF products have different speeds.

Temperature affects the rate of all chemical reactions. More heat = faster reactions. Less heat = slower reactions. Several time-dependent chemical reactions occur when the A-side meets the B-side. Too much or not enough heat can throw off the precisely controlled reaction timing, which is why we formulate two versions of the same product. We want the product installed with the same physical properties and performance, regardless of the season.

When we talk about temperature for spray foam installation purposes, we really mean the actual substrate and ambient temperatures.

The outside air temperature may influence the temperature of everything on a jobsite, but ultimately is irrelevant for product speed selection purposes. The substrate temperature determines the product speed because that is where most of the chemical reactions occur and because it usually has a large amount of mass compared to the air surrounding it. It takes a lot more energy to raise the temperature of a concrete foundation or a piece of wood than it takes to raise the air temperature. This means that a cold substrate may act as a heat sink, taking energy out of the reaction, or a hot substrate can contribute energy to the reaction. The chemicals react in an environment determined by the substrate, which is why this is the temperature to focus on.

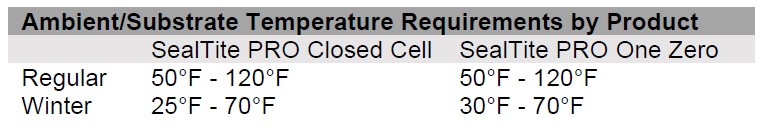

Winter speed products counteract lower substrate temperatures and allow the foam to cure properly, creating a stronger bond to the substrate. Spraying winter-speed products on warm substrates results in an increase in desired reactivity, which leads to poor physical properties, reduced yield, gun clogging, and distorted patterns. Spraying regular-speed products onto cold substrates causes reduced reactivity, poor adhesion, and friable foam. Always refer to the appropriate product application guide for substrate and ambient temperature requirements for each product speed.

As you can see from the substrate temperature recommendations above, there is some overlap between the two product speeds. We intentionally formulate this feature in our products to accommodate changing substrate temperatures throughout the day. Substrates that are very cold in the morning often heat up as the day goes on.

We recommend that spray foam applicators first measure the substrate temperature before installation, review the product’s temperature requirements to ensure the product speed matches the job site conditions, and then routinely check the substrate temperature throughout the day to ensure they’re within the limitations.

For ordering and inventory management purposes, we recommend ordering material according to the temperatures you expect to experience in your area and the specific jobs you plan to spray. For example, a retrofit roofline project in the winter may have substrate temperature greater than 70°F. A winter speed may be required if spraying outside or on substrates colder than 50°F.

Beginning in the early fall when temperatures can vary from hot to cold, we advise customers that their first order with winter speed product contain a 50/50 mixture of winter and regular speed products. This provides enough flexibility to use the winter speed on colder days and at jobs with colder substrate temperatures, and the regular speed for warmer days or on warmer substrates.

If you have any questions about which material to order in your area, contact your CSFI Sales or Technical Service Representative.